PRODUCTION CAPABILITIES

The production capabilities of the plant in Piotrków Trybunalski allows for a wide range of various projects, where the main components are steel structures, both small and large and large-scale as well. The entire modern infrastructure of the halls is adapted to the production of structures in a continuous cycle. In the production hall there are devices such as a continuous shot blasting chamber and a paint shop where, naturally, at the end of this system, a ready structure comes out, which can be sent directly to the customer or assembled and equipped with the necessary hydraulic and electrical components both inside the hall and assembled on an external test site.

FABRICATION WORKSHOP

- We have got a production hall with area of: 102x24x11 meters (l x b x h)

- Painting hall: 36x24x11 meters (l x b x h)

- Blasting chamber SciTeex BLASTLUX PC-BL 1254m2 11,9×5,0x4,1 (l x b x h)

- Clean assembly area: 36x24x11 meters (l x b x h)

- Testing & erection area: 1350 m2 90×15 meters (l x b)

- Lifting capacities: 3 overhead cranes of SWL 20T each.

CUTTING

- Plasma cutting: STIGAL VX STANDARD table area 6000×2000 (plasma or gas cutting)

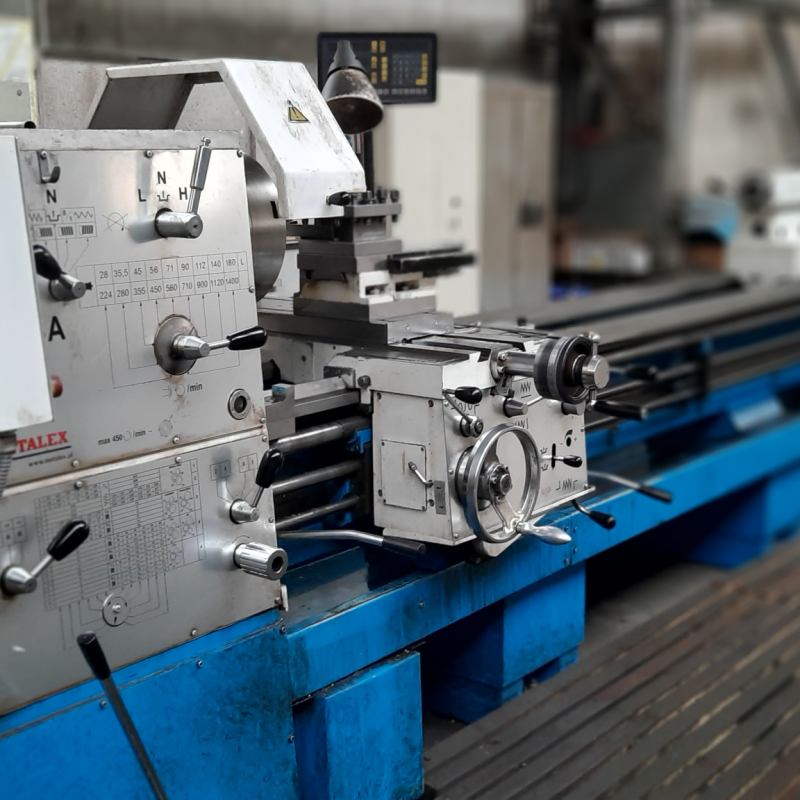

MILLING MACHINES:

- TBI VC1270 SMART MILL machining center

- Universal lathe FAT TUR 63 A / modernized in 2018, equipped with measuring rulers

- WARCOM MAXIMA 30-13 / 16 hydraulic shears

- GEKA PUMA 110S SEMIPAXY CNC punching machine

- BEKAMAK 360DGH band saw

- BEKAMAK 270DGH band saw

- GM-SB-50NCB semi-automatic mandrel bender

- PAX WR-50 radial drilling machine